The steel story: doing some heavy lifting

Journalist Glen Humphries and photographer Sylvia Liber pull back the steel curtain and take you deep inside BlueScope's Port Kembla steelworks.

2 May 2016

After the slab caster, the next stage in the journey of steel is slab handling.

While the name of this section does neatly describe what they do here, there really is a bit more to it.

Because, keep in mind that what they’re handling are long slabs of steel that weigh as much as 20 tonnes.

That’s not something you can lift up and carry on your shoulder.

And they handle them two at a time, while they’re still really hot from the slab caster.

So there’s some serious handling going on here.

After the steel leaves the caster, it gets sliced into slabs by gas torches.

Then it gets an eight digit code painted on its end, which helps track it as it goes on the rest of its journey.

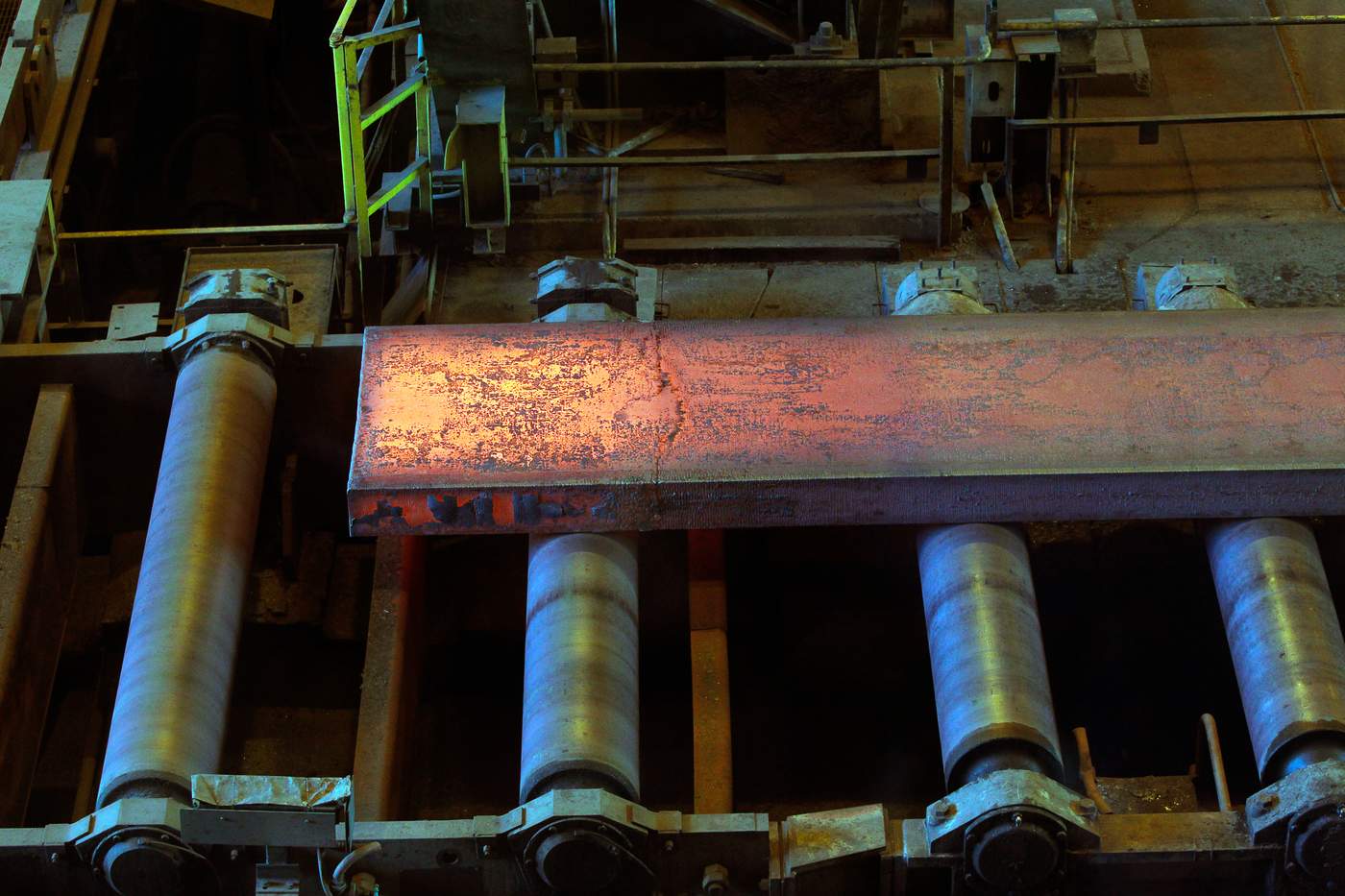

The slabs, still glowing red, move away from the caster and down a length of rollers.

They’re on their way towards a crane with four prongs that are used to grip a slab.

Much like a person playing one of those magic claw machines with aims on getting one particular stuffed toy, the crane driver moves the prongs back and forwards over a slab until it’s in perfect position.

Then it goes down and snares the slab.

The driver will then manouevre that slab onto another to pick up both of them - that’s 40 tonnes of steel - and carry them to a rail wagon known in the steelmaking game as a rake.

Over the course of a day, the cranes will move more than 400 slabs - around 8500 tonnes - this way.

The slabs then travel by rail to the slab yard - which is a bit of a misnomer as there are actually three yards.

Four if you count the overflow yard.

Two of the three main yards service the hot strip mill, while the third is linked to the plate mill.

There are two yards dedicated to the hot strip mill because that gets through a lot more slabs - more than 8000 tonnes a day compared to about 5000 tonnes a week at the plate mill.

Slabs sit in the yards in stacks of as many as 13, their unique digits clearly visible at each end.

Some of the yards are open to the elements and the surface of the slabs does start to form a coating of rust, which doesn’t damage the slabs and which is removed in the mills.

In the yards, the outside of the slabs starts to resemble that blue-grey colour we expect from steel.

But the insides of the slabs can still be hot - it’s not unusual to see a heat shimmer rising over the yards (a slab will take between three and four days to air-cool to a stage where you can touch them with a bare hand)

Large cranes that straddle the yards are used to pick up the slabs.

They can pick up anywhere between one and five slabs depending on the weight.

The slabs then get delivered to the mills at the end of the yard, where they go on one of two different journeys.