The steel story:

slab casting

Journalist Glen Humphries and photographer Sylvia Liber pull back the steel curtain and take you deep inside BlueScope's Port Kembla steelworks.

25 April 2016

Hardwood, rice hulls and the leftover shavings from making nails are among the more unusual ingredients used to make steel.

The hardwood is used in the BOS vessel from time to time, should the steel recipe need tinkering.

And the rice hulls and nail chips?

They get used in the casting stage - where the molten steel from the BOS vessel becomes a long slab.

But there’s a stage between the BOS and the slabcaster - steel treatment (all three sections are contained in one very, very large shed).

Once the molten steel is poured out of the BOS vessel and into another ladle, it goes to steel treatment.

As they say, the BOS gets the raw materials 90 per cent of the way to being steel and the treatment section does the last 10 per cent.

Slag is again added to the molten steel with the aim to draw out any other impurities.

Also, a device called a vacuum degasser sucks the molten steel up and pulls out any unwanted gases.

The molten steel is then poured into the top of the slab caster - essentially a long mould that sets it into slabs.

This is where those rice hulls and nail chips (the bits shaved off to make a point at the end of the nail) are used.

The former is used to cover the steel and insulate it as it waits to enter the slab caster - it will burn off without leaving any residue.

The latter is used at the start of a cast while it’s returning to full speed.

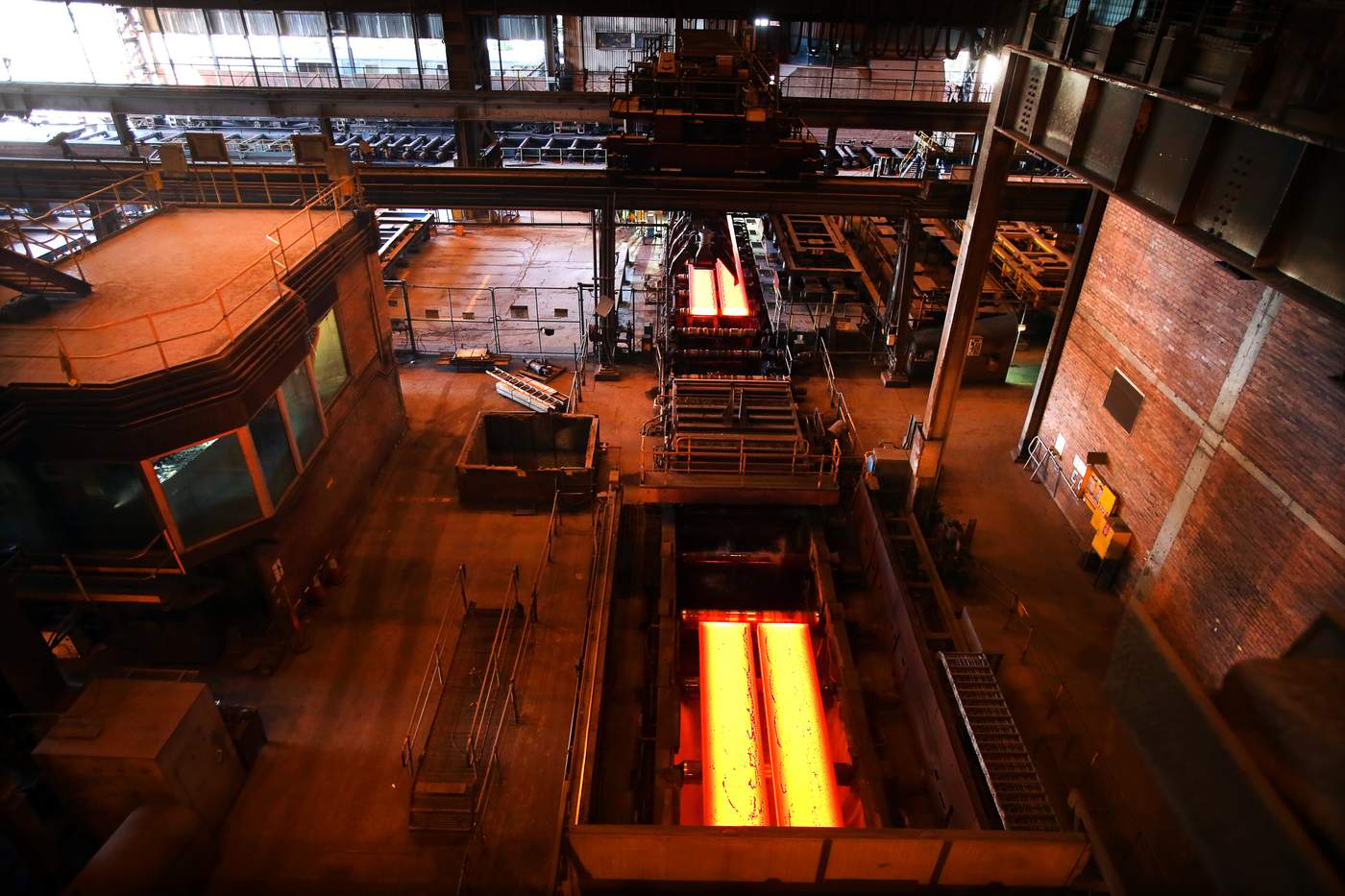

The slabs come out the bottom of the caster glowing red-hot and then gas torches cut them into predetermined lengths – as short as 4.5 metres or as long as 13 metres.

During the BOS and steel casting process a nearby lab is keeping tabs on things.

At around eight stages in the process, a sample of the steel is taken and sent to the lab via a capsule that is shot through a system of vacuum pipes (like those in a supermarket that take the cash from the checkout to elsewhere in the building).

Each sample takes the form of a thick steel disc about the size of a 50-cent piece.

It’s analysed and the chemical composition is sent back to allow for any adjustments to whichever of the more than 100 steel “recipes” is being used.

It’s a fast-paced job in the lab - with the blast furnace making 20 loads a day it adds up to more than 200 sample tests every 24 hours.

These test results are kept and form what is basically the DNA of each batch of steel made at BlueScope.

Once the steel leaves Port Kembla, a customer can send a sample back and a lab analysis can track down exactly which batch on which day that steel came from.

The testing can also identify if it is BlueScope steel at all - which has happened when a customer sends back a sample of flawed steel it mistakenly believes has come from BlueScope.